COMPREHENSIVE POLYMER SOLUTIONS

Local Warehousing & Just-in-Time Supply

Minimize downtime and manage inventory costs with our reliable stocking service. We maintain ready stock of high-demand grades in Pakistan's key industrial zones, reducing lead times and offering flexible, just-in-time solutions for both local and international buyers

Global Sourcing & Trading

With over 50 years of market intelligence, we have built deep-rooted networks across Asia, the Middle East, and Europe. We source directly from top-tier global producers like Sabic, LG Chem, and Formosa, ensuring traceable, consistent, and certified materials for your production lines

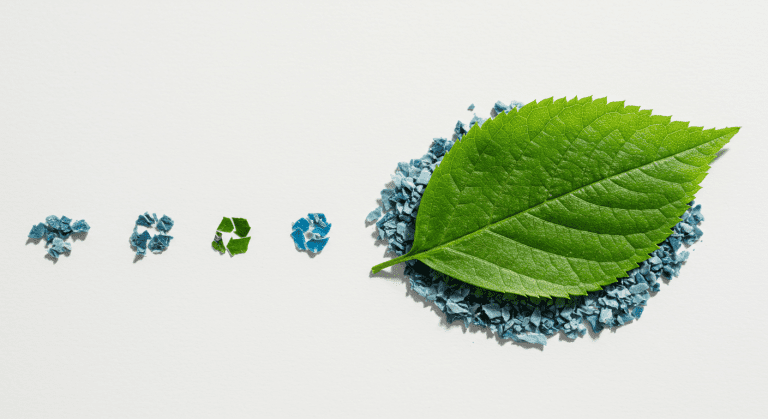

Sustainable & Recycled Material Solutions

We are committed to supporting the circular economy. We actively source and supply post-industrial and post-consumer recycled (PCR) granules, including reprocessed PE, PP, and PET, to help our clients meet their sustainability goals with cost-effective, eco-conscious options

Custom Compounding & Technical Support

our unique products require precise material properties. Our in-house team offers on-site technical support and custom grade matching to help you select or develop the perfect polymer compound. We ensure your materials meet exact performance, color, and processing requirements

Let's Discuss Your Material Needs

Whether you have a specific grade in mind or require technical support to find the right solution, our team is ready to assist. Contact us today for a custom quote or to speak with a polymer specialist